The Future of Manufacturing (Seminar)

I just started a seminar at sprout aimed at exploring how to use and make digital fabrication tools for the production of mass market goods. We had our first meeting this past Sunday brainstorming some ideas of what we want to pursue.

When: Sundays at 3pm.

Where: Sprout 339R Summer St, Somerville MA

The Future of Manufacturing

We are currently seeing the emergence of new technology and culture around manufacturing. Computer-controlled fabrication technology (CNC routers, laser cutters, 3D printers) open up opportunities to change the way we interact with the production of goods. Traditionally manufacturing has been built around large investment in specialized factories and tools to produce the lowest cost for runs of millions of units. These new tools emphasize flexibility instead of efficiency. This allows for the production of objects with little overhead, lowering the barriers to engage in manufacturing. Little risk and investment means a more democratic and diverse manufacturing world. However, most objects we consume are still made in a traditional way. Some tools, like CNC milling machines, have become industry standard. Injection mold making is now mostly done on CNC equipment, but molds still run from $25,000 to $500,000. On the other hand 3D printers are still relegated to prototyping, hobbyists, and high-end design objects. Most tools are still price prohibitive to make products for the mass market.

From the cultural side, we have the emergence of the craft, DIY, and open-source movements. The craft movement emphasizes small-scale, personalized production. Crafted products are primarily small “gifts” that are affordable but with a small premium because it is: different, ethically produced, directly from the maker. The DIY movement has developed a community of people interested in making their own tools, usually cheaper than commercial ones. Open-source provides a democratic development process, though it has not made much headway outside of software. There is also an increased interest in personally/artisanally produced goods, especially seen in agriculture (CSAs) and foods.

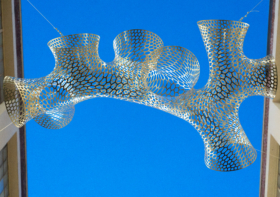

This seminar aims to explore how we can use emerging digital fabrication tools to engage in the small-scale production of goods for the mass market. How can this new form of manufacturing compete with the traditional? What is the new factory? Is it factory as organism instead of factory as machine, emphasizing flexibility and integration? Or is the factory non-existent? We can approach this from several different fronts. We can develop tools or tool chains that are low cost, flexible ways to fabricate objects. This does not have be as general purpose as something like a metal 3D printer, but could very specific to a certain product, eg ceramic housewares. We can imagine new ways to share knowledge about production techniques. We can try to bring the factory and the consumer closer together.

The seminar is an opportunity to share knowledge, collaborate on projects, and brainstorm new ideas. Each week, a person/persons will present some topic, for instance:

* a project proposal

* a project’s progress

* a technical topic, eg how to build a CNC router

* a manufacturing technology, eg how is something made

* thoughts or research into broader ideas: new ways to engage in manufacturing

Tom

was this seminar recorded – is it available for viewing?

David

This is an extremely interesting topic. I am currently completing a Masters Degree in Vehicle Design at the Royal College of Art in London. Do you know if there’s anyone I can contact to get seminar notes or any more information? I’m possibly going to arrange a similar interdisciplinary seminar at the RCA.