prototyping with the Form 1+

We recently welcomed a Form 1+ 3D-printer to our office. Even though we have 5 (?!?) FDM printers in our office, we never use them for prototyping our jewelry designs because they simply are not suitable for the type of complex organic geometries that we favor. However, this new machine has disrupted our usual workflow; we’ve been using it almost every day to prototype parts for our new collection.

We recently welcomed a Form 1+ 3D-printer to our office. Even though we have 5 (?!?) FDM printers in our office, we never use them for prototyping our jewelry designs because they simply are not suitable for the type of complex organic geometries that we favor. However, this new machine has disrupted our usual workflow; we’ve been using it almost every day to prototype parts for our new collection.

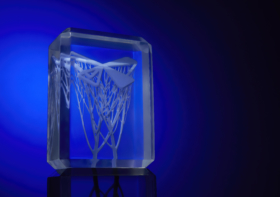

For those of you who aren’t familiar with it, the Form 1+ is a SLA 3D-printer. SLA, which stands for sterolithography, uses a laser to solidify liquid resin into plastic parts, layer by layer. There’s something mesmerizing about watching your design emerge from a tank of clear goo. Inside the orange box, the twinkling light of a laser beam traces cross sections, cross-linking polymers into a solid structure. The process eventually culminates in your digital design made physical but rendered oddly as a dripping stalactite, hanging down from the top of the machine.

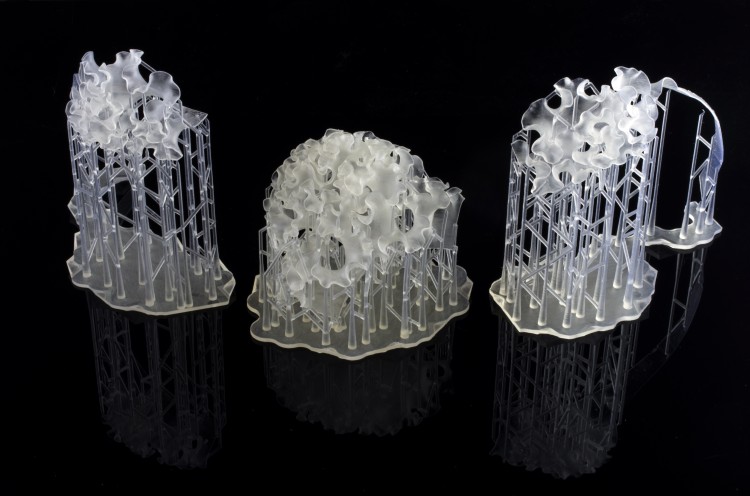

When parts come out of the machine they look like the image above. Each piece is printed in an optimal orientation and suspended on auto-generated scaffolding structures.

These are pretty easy to remove–except for the internal supports (which are EVIL). Depending on the fragility of the part, we remove the supports by snapping or cutting. This large necklace prototype was printed in 3 parts and glued together.

These are pretty easy to remove–except for the internal supports (which are EVIL). Depending on the fragility of the part, we remove the supports by snapping or cutting. This large necklace prototype was printed in 3 parts and glued together.

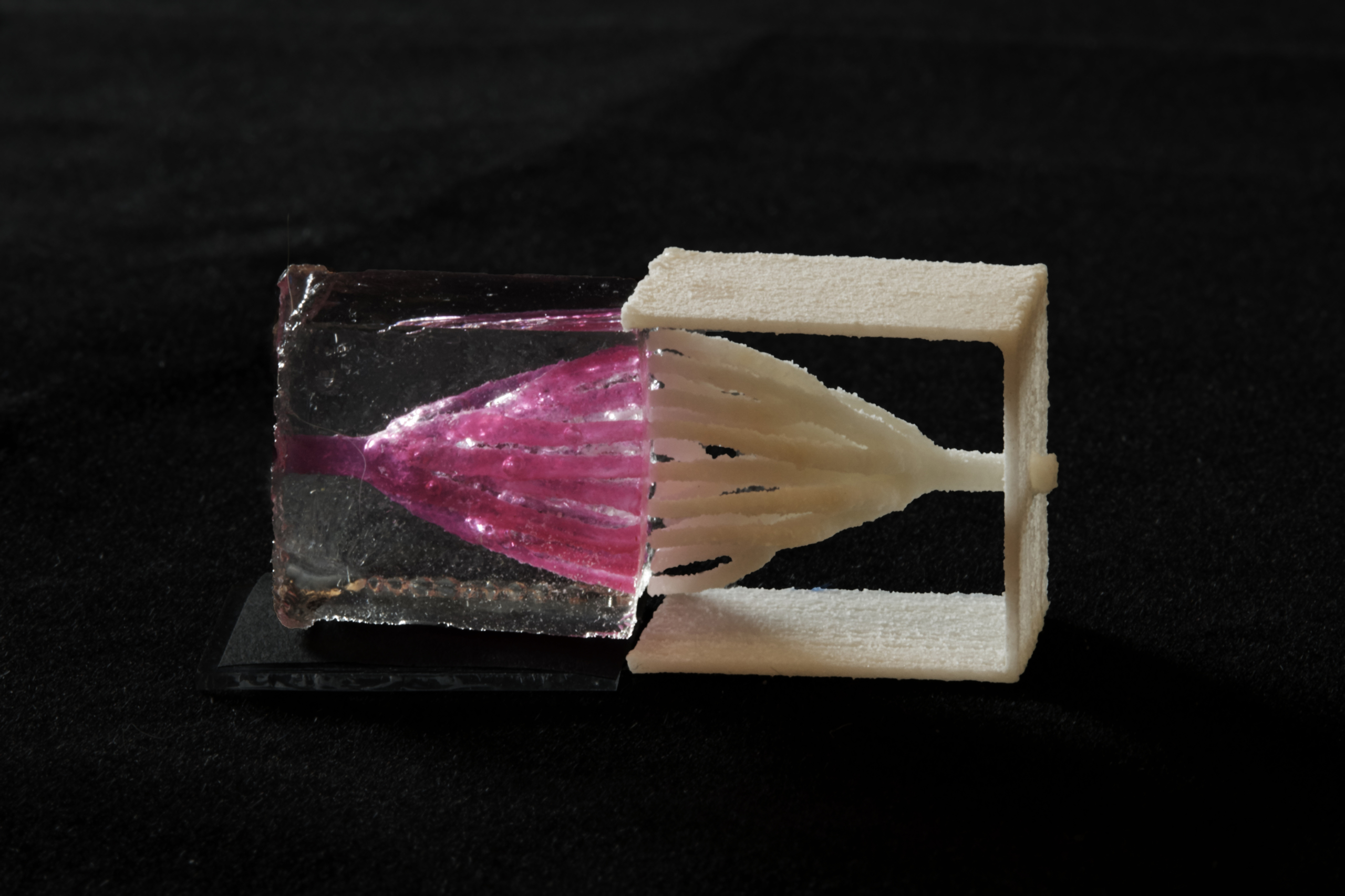

After being removed from the machine, the freshly printed parts are rinsed in Isopropyl Alcohol. The black specks on this piece came from our Isopropyl Alcohol rinse tank which was previously used for black resin prints.

After being removed from the machine, the freshly printed parts are rinsed in Isopropyl Alcohol. The black specks on this piece came from our Isopropyl Alcohol rinse tank which was previously used for black resin prints.

So far we have only used the least detailed resolution setting (.1mm) because we wanted our prints to be done quickly. But, I still find the prints quite satisfactory in terms of surface finish.

Scott Janousek

Hi Jessica & crew. Nice work. I don’t envy the person removing the support. Ha. ;)

If you ever need consumables on the spot, a second print due to your machine occupied, or just general help/tips & tricks, let me know. I have a year of experience printing on the Form platform, and I’m just down the street.

I can also recommend some really great artists that can airbrush.

Form on!

-sj