Corollaria Branch for MIT

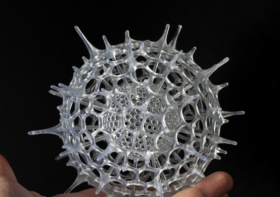

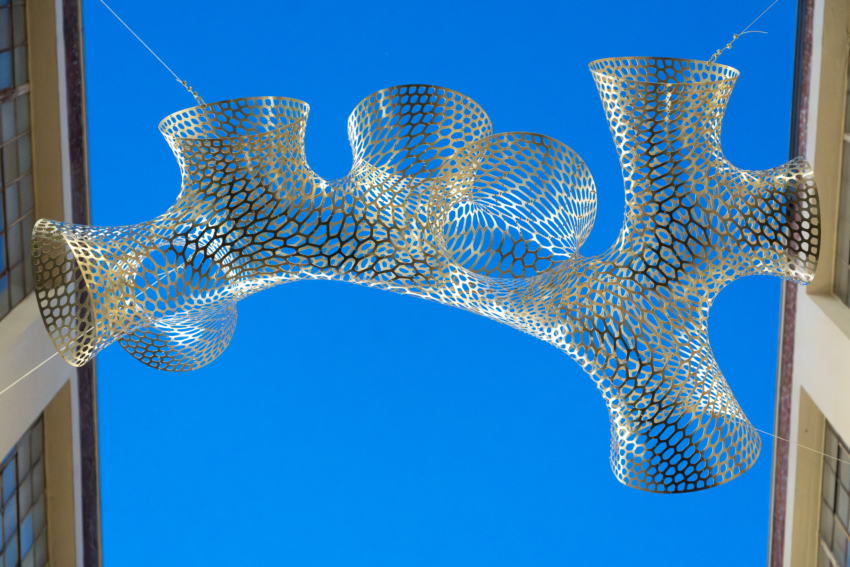

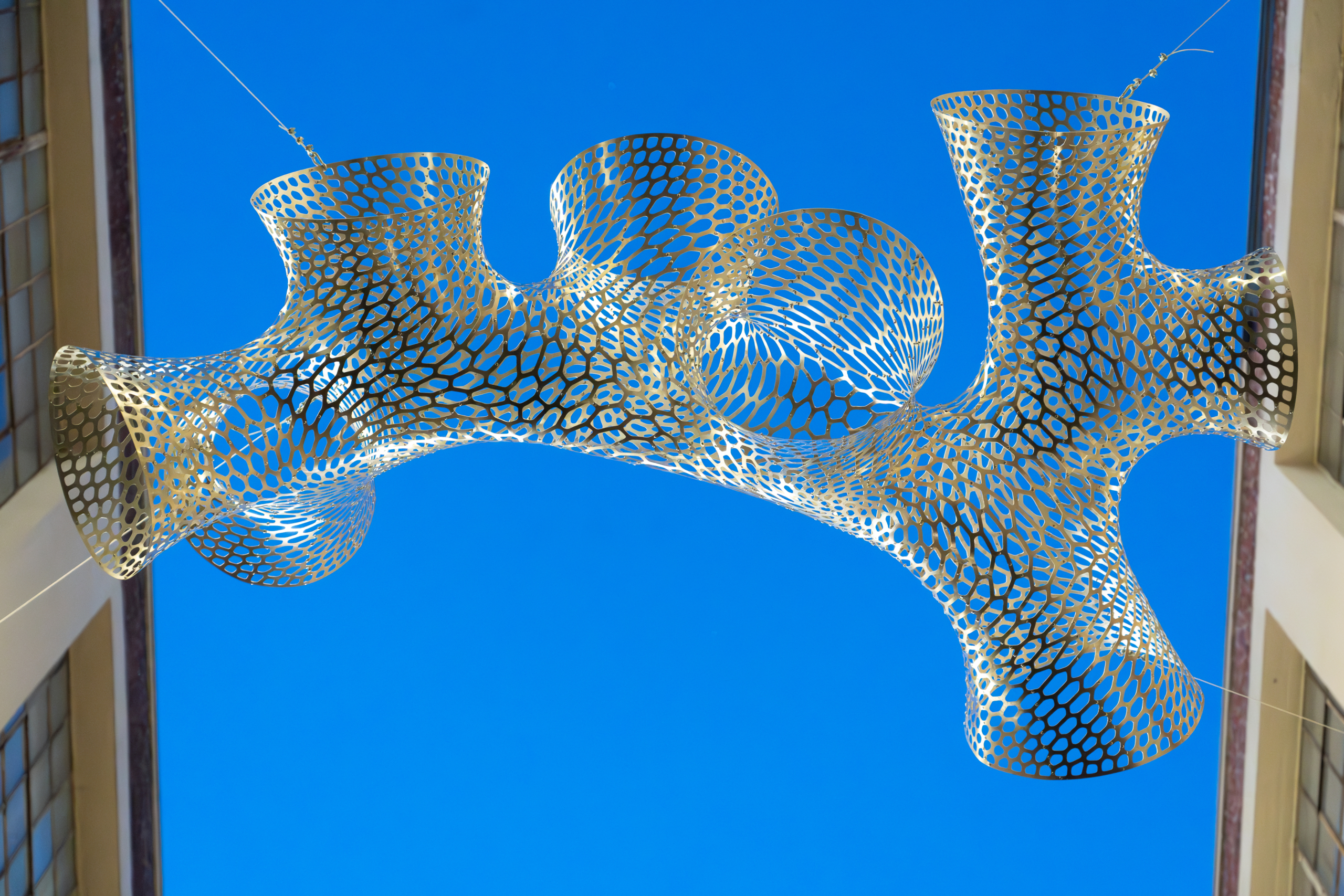

In the end of January, we traveled to MIT to teach a workshop for undergraduates hosted by MIT’s Morningside Academy for Design (MAD). The result of the weeklong workshop is a new sculpture, Corollaria Branch, which was built in collaboration with our students and is now installed in an outdoor courtyard at MIT. MAD produced a video about the workshop which you can watch below or on Youtube. The 9 foot long aluminum sculpture is made of 130 flat aluminum panels generated by custom software. The hollow tree-like form of the design is perforated by an intricate lace-work of cells whose scale and direction morph seamlessly along the surface. The mathematically generated patterns recall the organic forms of bryozoans, polypore mushrooms and plant tissues.

It was great to return to MIT for the first time in the 5 years since our move from Somerville to the Catskills. Prior to our big move, Jessica taught design classes there and both Jessica and Jesse attended MIT as undergraduates. It was also very challenging because now we were returning with two kids in toe. Trying to teach a workshop while also taking care of a 7 month old baby and a 2 year old is a different experience.

Workshop: Building Curvature

In the workshop, students learned how to construct surfaces with complex curvature from flat materials like paper, wood, or metal. Normally, flat sheets can only bend in one direction making so called ‘developable’ surfaces with zero Gaussian curvature. We used custom computational design tools to contort these materials into highly curved surfaces without any forming or creasing. Over the course of the week they learned how these tools work, designed some demo parts, and then as a group constructed a large sculpture using these techniques. The sculpture was constructed from dozens of laser cut aluminum panels connected by rivets which we cut, finished, and assembled on site.

Student work

Each student also designed and fabricated their own design using our software. The student pieces were lasercut from bristol paper and assembled with push rivets. A few examples can be found below (individual images are tagged with credits).

Credits and Thanks

Student team: Maxwell Berger, Joey Dong, Theo Gerst, Teresa Jiang, Adelmo Morrison Orozco, Simon Radhakrishnan, Pria Sawhney, Layla Stanton, and Gloria Zhu

Special thanks: Bill McKenna, Emily Katrencik and John Ochsendorf