Award Plaques for CMU’s STUDIO for Creative Inquiry

We recently created a set of sculptural award plaques for a new fund at The Frank-Ratchye STUDIO for Creative Inquiry at Carnegie Mellon University. The Moore Family Fund for underwriting creativity, knowledge, experimentation, research and yumminess will fund antidisciplinary undergraduate research (learn more here). Dan Moore (a senior technical artist at NVIDIA) commissioned us to design a unique set of perpetual award plaques that will hold the names of recipients over the next 75 years.

Rethinking the Award Plaque

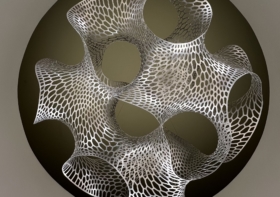

Typical award plaques are simple rectangular slabs with a grid of metal nameplates, each engraved year after year. We wanted to break away from that rigid structure and explore a more organic, cellular design. Carved from rich walnut, these plaques have flowing, sculptural contours that evoke natural growth processes. Instead of a traditional grid, the black nameplates are arranged within an intricate, algorithmically generated pattern—reminiscent of plant cells or the skeletal structures of microscopic radiolaria.

To make them extra special (and meet the request to make them fancy), we adorned the plaques with intricate maple inlays, creating a striking contrast that highlights the delicate cellular network. The result is a fusion of nature and computation, celebrating creativity and complexity—perfectly fitting for an award dedicated to interdisciplinary exploration.

Materials / Fabrication

This design consists of three materials: walnut for the base, maple veneer for the inlay, and aluminum for the nameplates. While we were able to fabricate all the wood components in-house, we had to outsource the metal parts since we don’t have a reliable way to cut aluminum ourselves.

We visited Ghent Wood Products, a local lumber mill, to source the walnut. We ended up buying a MASSIVE slab of walnut. We considered buying smaller pieces and joining them together or buying pre-made walnut butcher block but the price was going to be similar for a worse result. The slab we bought is 12 feet long, 1.5″ thick and 23″ wide at the widest point. The entire piece is not suitable for plaques due to a split on one end and some large knots. We’ll have to find some other use for the rest of the wood.

For the inlay, we used paper-backed maple veneer. We also tried unbacked veneer, but it expanded too much when glue was applied, throwing off the fit. That misstep resulted in the tedious task of picking out the failed inlay with dental picks (fun times).

The aluminum name plates were made by Xometry. They were lasercut with a fiber laser from aluminum. After cutting, they were be beadblasted, anodized black and put in tagged baggies. Each one is a unique shape so we need to keep track of which is which!

Prototyping

Before committing to the full plaques, we ran through the fabrication process on a smaller piece of walnut as a test. We used our ShopBot Desktop CNC to plane the surface, cut out the shape, and round over the edges. Our Trotec laser cutter handled the maple veneer cutting and rastered pockets into the walnut for inlay placement. After gluing the veneer into the walnut, we clamped everything and let it set.

The test run was worth it—we discovered some planing marks that didn’t sand out completely and slightly oversanded the veneer in one spot, creating a dark patch.

Software

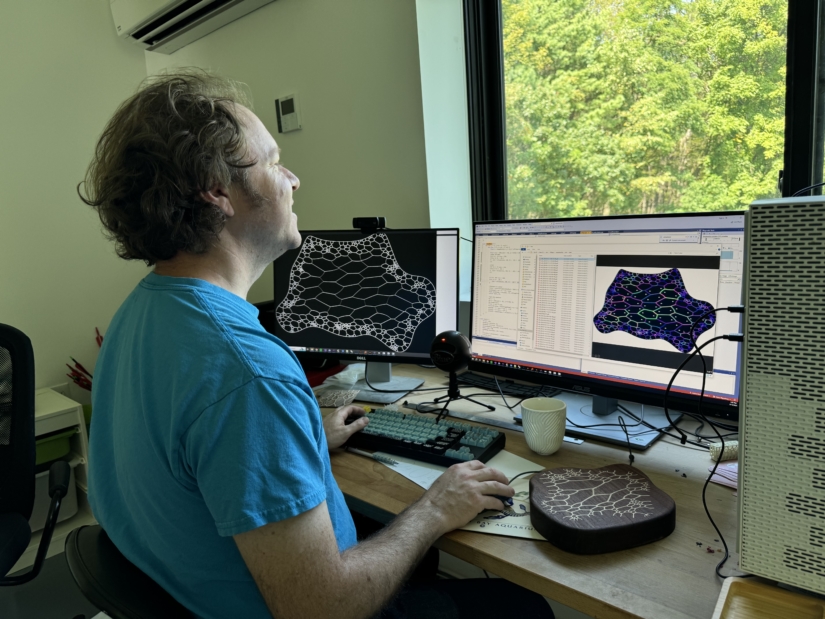

The plaques build off our Corollaria design software (some background in our blog here). Like most of our projects, our custom software is doing the heavy lifting but it’s aided by some back and forth in Rhino. We figured out the overall shapes and sizes of the plaques in Rhino and then bring them into our C++ software to grow the cellular patterns. After that, it’s back to Rhino where we used grasshopper to offset some of the cells for the name plates and number everything for fabrication. Visualization renderings were done in Blender using the built-in cycles render engine.

This project was a fantastic blend of design, craft, and computation—exactly the kind of challenge we love. From sourcing the perfect walnut slab to fine-tuning the cellular patterns, every step was an adventure (even the dental pick rescue mission). We had a great time bringing these plaques to life and would love to explore more custom award designs in the future. If you’re looking for something beyond the ordinary, let’s make it happen!