the secret to clean laser cutting: Designing a better laser nozzle using 3D-printing

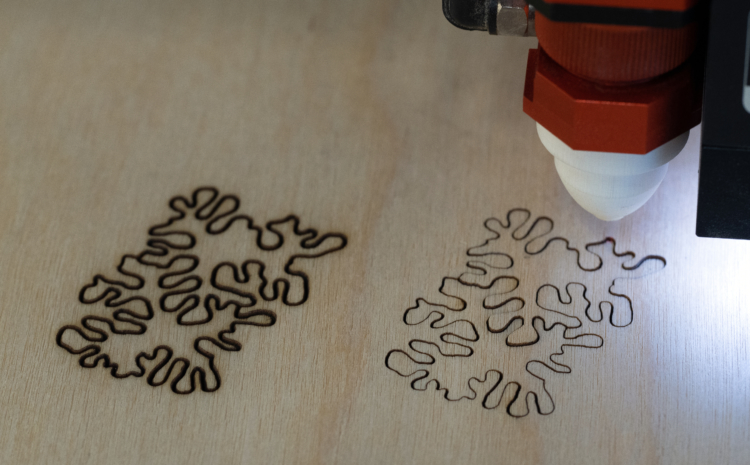

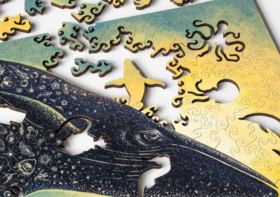

People often ask us for tips on how to make lasercut jigsaw puzzles. In fact, our most popular blog post is on our quest for the perfect plywood for lasercutting. We’re also often asked how do we get our cuts so clean? There are a lot of elements to that but an important one is air.

Laser cutters use a stream of compressed air called an “air assist” to blow away smoke and debris as they cut. This keeps the lens clean and quickly moves the hot and dirty smoke away from the work piece. An important thing for a good laser cutter to have is a coaxial air assist, meaning the laser beam and the air stream point in the same direction, rather than having the air blow from the side. However that’s not all; it turns out the quality of your air can vary greatly. It’s not about how hard you blow, but how smooth the air is. You want the air to be very efficient otherwise it can be like blowing on a fire. Rather than removing smoke, you end up stoking the burn making cuts worse rather than better. This quality is called laminar flow (as opposed to turbulent flow).

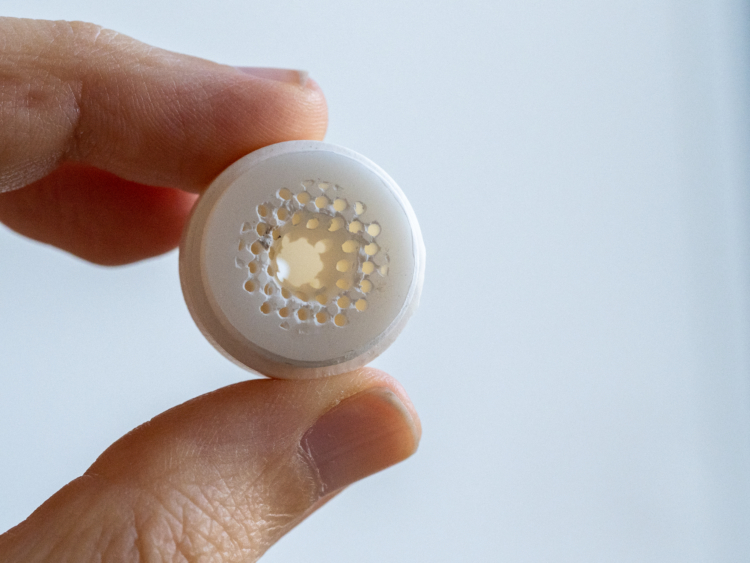

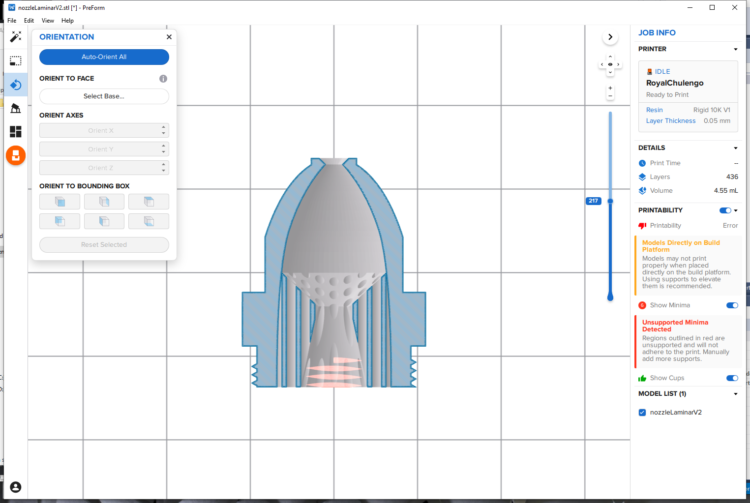

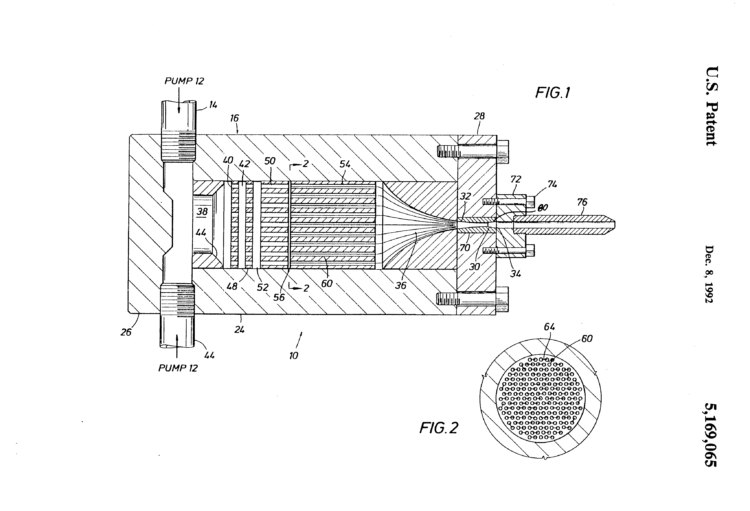

To improve our air assist, we have developed a custom 3D printed nozzle for our lasercutter. There isn’t much information out there for designing air nozzles, except for spray guns which have a very different application. However, there are a lot of resources for designing DIY laminar flow nozzles for water, and that’s for one reason: super soakers. I found a great resource with lots of patents for nozzles called Super Soaker Central. There were 2 main takeaways I got from this: you want the exit of the nozzle to be very sharp and you can use thin channels in the nozzle to columnate the air and remove turbulence.

There a number of limitations for a laser nozzle that you don’t have for a water nozzle. Most notably, you cannot block the path of the laser. Water can go around obstacles; lasers cannot. For flow, you ideally block off the center and let the columnated air come together at the end, but that’s not possible. Also, your space is very limited. A laser lens has a specific height when it’s in focus, so your nozzle can only occupy that limited area between the lens and the work piece.

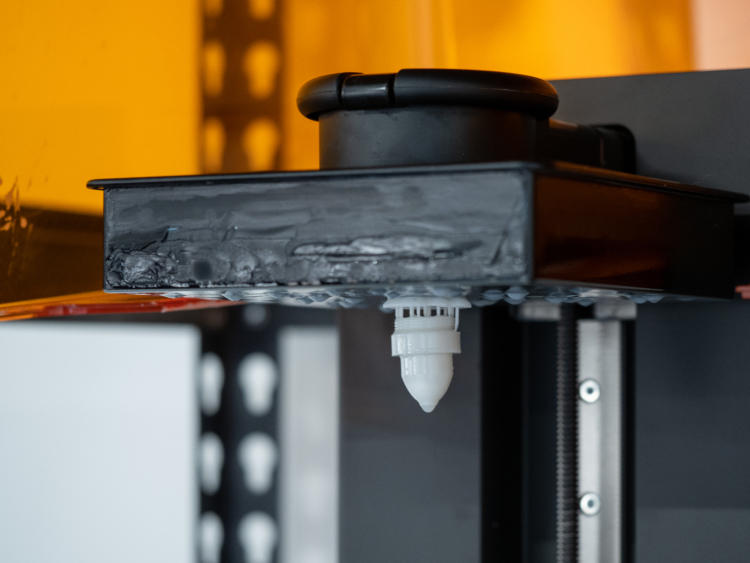

I put together this nozzle design for our Trotec machines. I am not an aerodynamics engineer so it could probably be a lot better, but the difference in the feel of the air is dramatic. The improvement in cut quality is subtle but makes a big difference in production when you’re cutting 100 puzzles a day.

These nozzles were printed on our Formlabs Form 2 3D printer using their new Rigid 10K resin. The high performance resin helps keep the edge of the nozzle opening sharp and round while high-pressure, hot air is constantly blowing out.

where can I get the nozzle?

Hello everyone! Since posting this yesterday we have gotten a ton of emails, tweets, and blog comments all asking about how to get the nozzle. The project is now live on Hackaday.io under a non-commercial license. If you would like to purchase a commerical license or just support the project you can do that here.

Marty

hi can you share the design?

Jason

This is very … cool! Would you be open to making the design of the nozzle available for others to print? Would love to have an open-source design we can help tweak for efficiency.

sirus

Could you post the STL of this?

Cali

Can you upload the CAD files for your nervous system laminar flow nozzle for the rest of us to gratefully try out?

Thanks!

Augie millares

This is very informative.

I have a trotec machine too… how can I get the nozzle you have… Please let me know. Thanks.

Ramon Padilla

Are you going to be selling these?

Daniel

Wow, great Work. I never saw any Investigation in different flow behavior on nozzles for laser systems. Do you mind Sharing the Design so people can Print the nozzle themselves and TRX different designs?

Appreciated from a tinker

Joe

Fantastic read I’d say the results were way better than ‘subtle’?! Are you selling these nozzles? Do you make/can you offer them for Epilog machines too? If not are the print files available please? Would love to try these on my epilog machines, we cut card which as you’re no doubt aware is notoriously bad for laser burn, especially with lighter colours so this could really help us. Please DM me if you have a moment?

Chris Madar

We have a small epilog machine (120W Fusion Pro 32) without proper air assist – just with a piece of hose blowing air from the side. Based on this article I designed a nozzle to redirect the flow more like here and tried the first prototype today. The results were promising however my nozzle had allot of leakage so have made some tweaks. If you have a similar laser I can share the file with you when I’ve finished testing. Currently printing on a polyjet as our form 2 is temporarily out of action however print should work well on an SLA.

Joe Holden

Amazing thanks Chris. We use 40w Epilog mini’s, but I believe they have the same head/nozzle system. joe (at) cakeshop (dot) com. Cheers :)

Daniel Musheev

We’d love to see this file! If possible could you forward us the link?

Jessica

It’s in the end of the blog post

Andreas Seibert

I would really appreciate a file for a epilog nozzle, i use fusion m2. Would save me a lot of time cutting puzzles without foil.

Please contact me Chris! All the best for Jessica in the next weeks!! Cheers ! Andreas@custompuzzles-xxl.com

RAUL COMENGE

Buenos días la verdad que es una idea genial y muy currada, sorprendente

me gustaría saber si esta boquilla la tienen a la venta y si es así que precio

tiene nosotros disponemos de varias máquinas Trotec ( speedy 300 y 400 )

y estaríamos interesado es este producto si lo tienen a la venta

Esperando noticias suyas

Raúl Comenge

Gráficas Comenge

Marty

can you share your design? 😀

Gary Wiant

Great article, are you planning on making these to fit Thunder Laser Nozzles? I’d be very interested in getting one.

Thank you for your hard work & informative article

Tom De Weyer

Is the stl available to try this out?

Shane

That looks amazing. Do you plan to offer these for sale in your store?

T-Rex

That look very cool. Can I get the STL files or buy one?

James Bradsaw

Are you going to share this design, or make it open sourced so others can download it and play with it?

Would love to try this on my k40 and k50.

Jessica

Hello everyone! Thanks for your interest in our nozzle. We are figuring out the best way to share the design files and will be updating this post in the next couple of days

Grace X Lovejoy

Thank you!!! 😃

Ace

I would love to see this on thingiverse, I would print this in clear resin and give it a test drive for sure :) Looking forward to the STL :)

Michael Chernoff

I want to try this with our laser cutter. Is there a nozzle to attach an external air supply?

Matthew Juntunen

Fantastic work! Definitely interested in an stl. Kudos!

Wayne Knight

Very nice! Amazing what can results are possible with a little thinking outside of the box. Waiting for the .stl file.

Thanks

Wayne Knight

Have you thought about using the EDM process for making a metal version?

That process can make some nice, really small holes. Just a thought.

David

I knew I have seen this red anodized nozzle somewhere!

Own a Trotec as well.. maybe you should reach out to them and request a share from each laminar-flow-nozzle they sell.;-)

Grace X Lovejoy

Oh yes. I would very much like to print one too. This is a total game changer. Thank you!

Don Mayhew

Nice work!

Jim

Do you think it might also be possible to simply create a drop in plug that fits within the existing nozzle? That would make manufacturing and retro-fitting a very simple process.

Just wondering…

Rick

I would like to see this as open source. It can always get better.

Ivan

Looking forward to see your stl…

Ray

This is so cool! I’m curious about the air source. Are you using the common silver air pump or a compressor? If a compressor what PSI do you set the nozzle air too? I’ve seen somewhat similar cut comparisons with higher PSI air assist, but maybe with a laminar flow designed nozzle like this the PSI/air flow rate requirement for clean cuts is lower? Thanks!

Jesse Louis-Rosenberg

Yes, we use an external air compressor and typically run at 30 psi (though we run one laser at 20). I actually see the biggest difference at higher psi, since the extra pressure is actually being utilized where with the stock nozzle it just makes the air more turbulent. We haven’t tested with the internal air compressor

Ray

Awesome, thanks!

Michael Chernoff

I am making the assumption that you have an air hose that connects to the air nozzle. How do you keep the air hose out of the way of the incoming laser beam from the CO2 chamber?

Do you have problems with it kinking up or knocking into the stuff you are laser cutting? How do you manage this hose?

david naisuler

Looking forward to hearming more about this, and a chance to try any STLs that might be published on my K40. And thanks for the patent refs, they were very interesting reading.

Lewis Kleynhans

I would like the design please. Please keep us posted

thomas

this is a great thing. A friend of mine has a 3D-Printer and I would like tot try it out on my 50W Chinese CO2 Laser. Is there any possibilitie to get that file from you? Many thanks and all the Best – Thomas

Jessica

The nozzle is now available on Hackaday.io here: https://hackaday.io/project/176034-nervous-system-laminar-flow-laser-air-assist

Matthew Baggett

Got bored waiting for the release and made my own for my cheapo K40 laser.

https://www.tinkercad.com/things/1t7v0rXc2LT

Taylor

Any results from use yet?

Yann Girard

Very interesting ! I wonder how much of the effect is due to the nozzle being closer, with opening more restricted, and how much is due the change in air flow though. It would be interesting to print another one without the “flow linearization” holes and compare results.

In our experience, closer and smaller nozzle, with more flow, was key to improve cutting quality.

Also, if you’re interested in reducing burning on the underside, it is just as easy as separating the board a few mm from the metal surface under (so it’s “floating”). We got totally clean undersides after trying that.

Jesse Louis-Rosenberg

We used another 3D printed design previously for years that just tried to have a smaller nozzle opening, closer to the piece, and it wasn’t nearly as good.

Yann Girard

Ok thanks for the reply ! Very interesting !

Michael Chernoff

I work at a University where I often 3D print parts for use in making a vacuum chamber using a Formlabs 2 SLA printer, using the Formlabs clear resin.

The resin prints can be annoyingly brittle, but if you 3D print it with a hole for a 1/8″-27 MNPT gas fitting (we use Solidworks for our designs, so we use the hole wizard, and add a 1/8″-27 MNPT hole using the wizard) you can use a 1/8″-27 tap to thread the hole, and then use a 1/8″-27 MNPT -to-1/4″ press fit adapter to add a 1/4″ tube for feeding air into the attachment.

.

Jesse Louis-Rosenberg

I haven’t used a lot of the “engineering” resins before, but we had been using clear nozzles for a while. I’m very happy with the results of the Rigid 10K so far. Seems more robust.

Robin Cook

Great job! Very impressive. You should apply for a patent. I have an Epilog Helix. I would be interested in buying one if you make one that will fit my machine. Thanks for sharing.

shawn

What type of printer do you use to print your designs on your puzzles?

Eric Jorgensen

Hey. A friend of mine has a patent on a nozzle to provide laminar gas flow in laser-plasma cutting systems. It’s probably expired by now, that’s not the point. No, i don’t have the number.

I chatted with him about this tonight, he looked at your design and said he basically used the same technique as the supersoaker design.

But he pointed out that a hyperbolic curve is mentioned in both his design and the supersoaker patent, and that you didn’t implement it. And that it matters.

Just, FYI.

Jesse Louis-Rosenberg

I saw conflicting design information. Another design guide I saw on water jet nozzles had a profile more like my design. Because of the limited space of a laser nozzle, a hyperbolic shape would remove a lot of the room for the column channels, which seemed more important. Besides, the first design worked well, so I didn’t try exploring others. Feel free to add designs/discussion to the hackaday project page https://hackaday.io/project/176034-nervous-system-laminar-flow-laser-air-assist

JT Smith

I bought this and printed it on my Form 2, but it actually added more soot with this nozzle than the default nozzle. Any tips or tricks for getting it to work?

Jesse Louis-Rosenberg

The hackaday page has more details about our setup. https://hackaday.io/project/176034-nervous-system-laminar-flow-laser-air-assist

It also depends on what you are doing. Are you rastering or cutting? If your rastering, it will just blow material on to the top of the piece. You need to be cutting all the way through otherwise the smoke has no where to go. We also have a very strong exhaust.

Roy Sigurd Karlsbakk

I don’t have the Rigid 10K resin. Will this work with any of the other ones, like Tough something?

Jessica

sure.

russ sheard

Hi There,

I have been using a repositionable mask ( a 60# matte paper adhesive) for cutting puzzles………….once cut I have been

using Gorilla Tape to remove the mask……………this has worked well in protecting the graphic print.

My supplier is discontinuing the repositionable material . All the products I have tried are too sticky and won’t lift

with Gorilla Tape.

Can you suggest any alternatives I might try ? Thanks

Alex

Love the design, i have been playing around with nozzles for weeks now.

I would be concerned that it would be flammable and set the whole machine alight if the third mirror goes out of focus

Drew Van Zandt

Have you looked at gas lenses for welders? They have similar constraints, especially for MIG, where the wire must go through the center.

Corey Panno

I do not have a 3D printer. Will you sell a nozzle?